NEWS

Principle of variable process heat exchanger

2014-09-23 01:09

At present, in the cold areas of northern my country, the traditional centralized heating method is mainly coal-fired. Due to smoke and dust emissions, severe weather phenomena such as haze and PM2.5 exceeding the standard occur in northern cities in winter. Therefore, in recent years, the country has vigorously promoted clean heating methods. Many buildings use water source heat pump units as heating hosts to replace traditional coal-fired boilers, and water-water water source heat pump units are mainly used. The existing water-water type water source heat pump units on the market mostly adopt the mode of water circuit switching for cooling and heating mode conversion: when cooling in summer, source water (underground water, river, river, lake water, etc.) enters the condenser of the unit to exchange heat with the refrigerant and take away the heat of condensation, and the end air conditioning water enters the evaporator of the unit to exchange heat with the refrigerant and release heat; when heating in winter, the source water enters the evaporator of the unit to exchange heat with the refrigerant and release heat. The end heating water enters the condenser of the unit to exchange heat with the refrigerant and take away the condensation heat. The water flow through the evaporator and the condenser is interchangeable in summer and winter, and the rated water flow of the evaporator and the condenser is very different, that is to say, the water flow through the same heat exchanger changes greatly in summer and winter, however, most of the existing heat exchangers are designed according to a fixed process, and the process of the heat exchanger does not change after the water flow rate changes, so that the water flow rate in the heat exchanger will change, thereby affecting the heat exchange performance or increasing the water resistance, thereby increasing the operating energy consumption of the water source heat pump unit and the system.

Secondly, with the country's attention to energy conservation and emission reduction, in order to effectively reduce building energy consumption, many buildings have adopted variable water central air-conditioning systems, especially the use of a pump variable flow system more and more. Most of the general central air conditioning systems use water-cooled chillers as the host. The existing water-cooled chillers use fixed-flow heat exchangers as evaporators and condensers. This fixed-flow heat exchanger is used in variable flow systems. When the water flow changes with the load, its water flow rate and water resistance will change, thus affecting the heat exchange effect of the heat exchanger and the energy consumption of the system.

In addition, in actual use, some water source heat pump units or water-cooled chillers have certain operating conditions (such as air conditioning conditions in transitional seasons, long-term refrigeration or long-term heating process conditions, etc.) due to the high evaporator outlet water temperature or low condenser inlet water temperature, and the compressor often operates under the minimum load, resulting in the phenomenon of high evaporation temperature or low condenser temperature, high evaporation temperature and low condensation pressure will lead to the existence of unsafe problems such as compressor overload, insufficient oil supply pressure difference of compressor and difficult loading. However, in some application occasions, the unit needs to operate under these harsh working conditions. If the heat exchange area of the heat exchanger can be reduced under these working conditions, the purpose of reducing evaporation temperature and increasing condensation temperature can be realized, thus ensuring the reliability and safety of the unit under harsh working conditions, however, the existing heat exchanger cannot change the heat exchange area during use.

In view of this, there is a heat exchanger with process conversion and variable heat exchange area on the market, which can be installed on water source heat pump units and water-cooled chillers as condensers, and can also be installed on flooded units as evaporators. When the water flow changes greatly, the water side process of the heat exchanger is changed through the action of the water chamber division and the conversion valve, thus improving the heat exchange efficiency. When the heat exchange area needs to be reduced, through the role of the water chamber and the conversion valve, some heat exchange tubes in the heat exchanger are not involved in heat exchange, thereby reducing the evaporation temperature or increasing the condensation temperature. The heat exchanger can significantly improve the operating efficiency of the unit through the change of the process, significantly reduce the energy consumption, and can improve the reliability and safety of the unit under harsh working conditions through the adjustment of the heat exchange area. It also has the characteristics of convenient installation and simple use, and can be widely used in various water source heat pump units and water-cooled chillers and other variable flow systems.

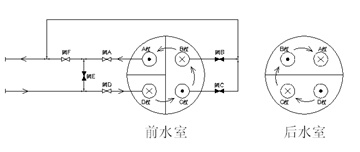

Four flow principle diagram

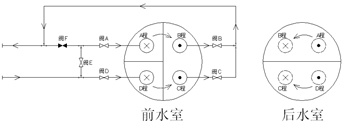

Schematic Diagram of Two Processes

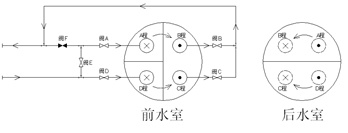

Schematic diagram of principle of transformed thermal area

Previous Page:

Related News

Contact Phone

Contact Address

Hantang Road, Industrial Concentration Zone, Dongping Town, Lishui District, Nanjing City

Copyright ©Nanjing Lengde Energy Saving Technology Co., Ltd.